Ambipar Site Services are front runners when it comes to confined space tank cleaning.

Ambipar Site Services invest heavily in some of the most advanced machinery in the industrial cleaning market and our ever expanding array of equipment & plant which includes specialist Machinery such as our new 2013 DISAB Centurion LN and Hercules High Flow Vacuum tankers.

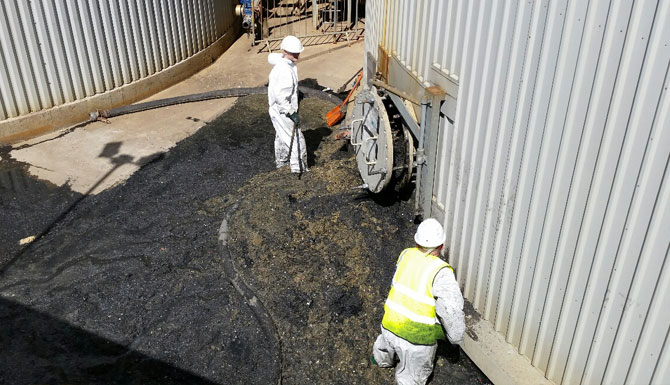

Combine the specialised machinery with our highly trained Engineers along with non-entry tank cleaning technology, the units can be operated remotely to minimise confined space entry. However this is not an option on some occasions and confined space entry is required to which our confined space trained teams regularly undertake large projects in environments such as oil refineries, Chemical plants, utilities and aerospace manufactures.

As added support with our tank cleaning projects, the Hercules and Disab High flow units with a 8″ suction hose where designed to solve the problem of removing heavy sludge from tanks. Working on 9000cfm airflow rather than vacuum the units boasts the ability to lift materials over incredible distances and vertical and horizontal lifts via the 360 degree hydraulic boom.

Ambipar Site Services are also front runners on Silo cleaning using the latest Cardox Co2 Systems.

Cardox has a variety of different tubes for specific applications. Tubes are filled with liquid carbon dioxide (exactly the same as a fire extinguisher). When energised by the application of a small electrical charge, the chemical heater instantly converts the liquid carbon dioxide to a gas. This conversion expands the CO2 volume and builds up pressure inside the tube until it causes the rupture disc at the end of the tube to burst. This releases the C02 – now 660 times the original volume – through a special discharge nozzle to create a powerful heaving force, at pressures up to 40,000 psi (3,000 bar). This all takes place in milliseconds.

Carbon dioxide gas is an inert gas that is commonly used in fire extinguishers, so it is safe to use without fear of generating secondary reaction with gases in the vessel / silo. In addition, the quick release of the gas refrigerates the discharge, bringing it to a temperature low enough to avoid ignition of any air-gas mixture inside the blocked vessel.

Our industrial services team offer a vast array of services including:

- Confined Space Tank cleaning

- General site Labour

- Drain Cleaning

- Ultra High Pressure Water Jetting

- Remote Tank Cleaning

- Gully Cleaning

- Wet well cleansing

- Filter media removal

- Silo Cleaning ( Cardox System )

Ambipar Site Services takes All Health and Safety requirements seriously and as a result all of our are highly trained and competent in High risk Confined Space Entry, CSCS or SCAT Safety Passport standards, Water Jetting up to 36,000psi, Blue water hygiene holders, Asbestos awareness, Manual handling & NPORS Operators.