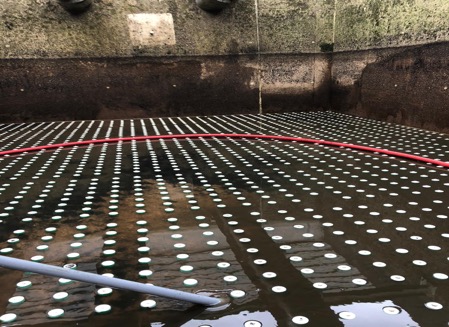

Enviroclear have developed a removal System for GAC (Granular Activated Carbon), that will allow for the safe transfer of Carbon from filter to filter, Removal and Bagging and Reloading, Minimising the costs of unforeseen remedial works when required. This eliminates the need of Bulk Transfer Tankers, additional reactivation costs ahead of planned schedules, and the need to have to transport the media of site, the system also allows for the removal of carbon that is unsuitable for reactivation. The system works by utilising water driven educator system, GAC is then passed over a Vibrating dewatering screen, where the dewatered carbon is discharged direct in to a 1M3 Bulk Bag. Water is then discharged into a holding tank and re-used to drive the Edactor. The system comes with its own generator and electric booster pump. Ensuring works can be carried out on sites with limited access and services.

GAC can either be stored on site, should remedial works be required within the filter, or transported of site for reactivation. The equipment can also be utilised for loading carbon on site, direct from Bulk Bags by gravity feeding the carbon into the Edactor Hopper.

The system has been utilised extensively throughout UK’s water utility companies.

Case Study 1

The client required the removal and bagging of activated carbon from 2 x carbon filters, with further transfer to River Itchen. The media was stored for approx. 1-2 weeks whilst remedial works were carried out on the filters. We then removed circa 25m3 of media from the River Itchen Filter, and transferred the media into filter 1, followed by us loading 25m3 of the Media into the River Itchen Filter. This was repeated for the second vessel, in conjunction with the first filter coming back online.

Case Study 2

The client required remedial works to be undertaken on the laterals of GAC filter. The carbon was removed and bagged on site, whilst the remedial works were completed and re installed on completion of Remedial Works.

Case Study 3

We were tasked by our client to remove carbon and transport back to the mainland, on completion of removal, inspect nozzles then reload Virgin media. The trailer system was utilised to remove and bag material on site, once inspected the filter was reloaded.

The benefits of utilising this method meant that transport costs were vastly reduced, down time of the process unit was minimised, and all aspects of the work, were under the control of 1 x company minimising the exposure to risk.